- What is a UK contract manufacturer?

- How to choose the right UK contract manufacturing partner

- Benefits of working with a UK contract manufacturer

- Common mistakes to avoid with contract manufacturers

UK Contract Manufacturer

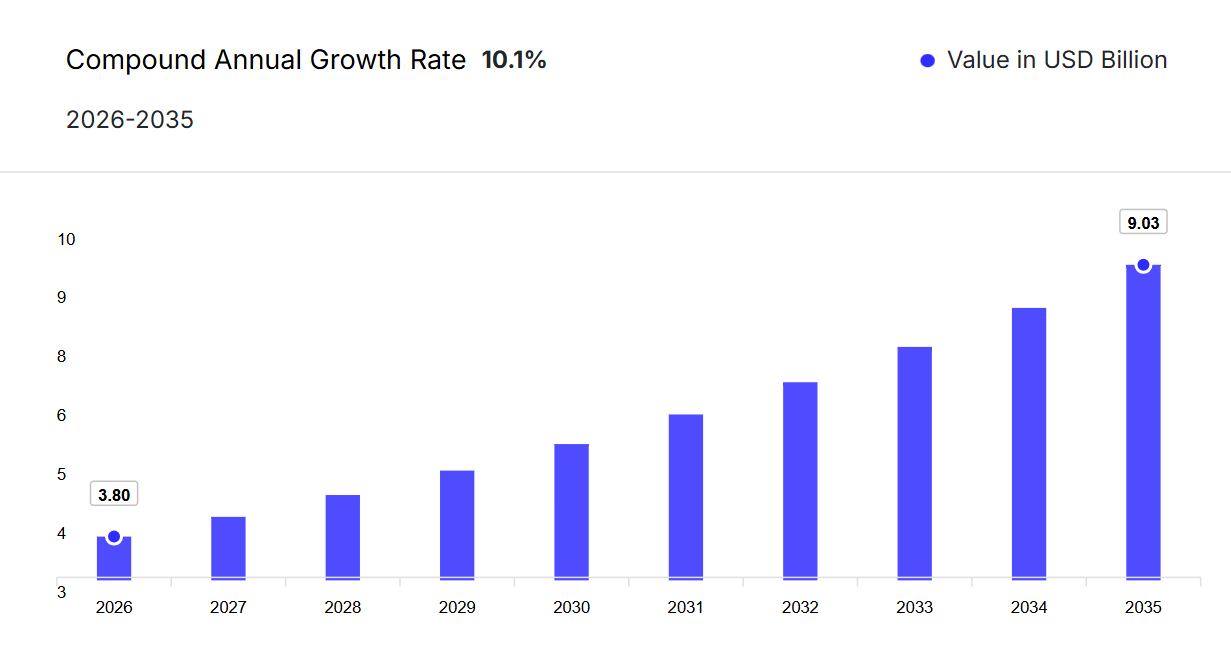

According to data from a leading market researcher, the UK dietary supplements market is valued at $3.45 billion (£2.57 billion) in 2025, and is expected to reach $9.03 (£6.72 billion) by 2035. There have never been more opportunities for brands that can respond quickly to consumer demand while maintaining strict quality standards.

For brand owners, procurement teams, and operational managers, partnering with a contract manufacturer represents a strategic decision that affects everything from product quality to time-to-market.

For brand owners, procurement teams, and operational managers, partnering with a contract manufacturer represents a strategic decision that affects everything from product quality to time-to-market.

A UK contract manufacturer is a third-party production specialist that manufactures products on behalf of your brand according to agreed specifications, quality standards, and production volumes. These manufacturers handle formulation development, ingredient sourcing, production processes, packaging, quality control, and delivery logistics while you retain ownership of your brand and product specifications.

Selecting the right UK-based manufacturing partner determines whether your products reach market on schedule, meet regulatory requirements, and align with your brand standards. In this guide, we explain what UK contract manufacturers do, why location matters, and how to evaluate potential partners based on capability, certification, and track record.

What Does a UK Contract Manufacturer Do?

A contract manufacturer operates as an extension of your business, producing finished products that meet your specifications without requiring you to build or operate your own production facility.

Core functions include:

- Formulation development: Working with your team to refine recipes and ensure ingredient compatibility

- Ingredient sourcing: Leveraging established supplier relationships to secure quality raw materials

- Production planning: Coordinating manufacturing schedules to meet your delivery requirements

- Powder blending and batch manufacturing: Executing production runs according to agreed specifications

- Quality control: Testing at multiple stages to verify product safety, potency, and consistency

- Packaging operations: Transforming bulk product into finished units with compliant labelling

- Storage services: Holding products in appropriate conditions until dispatch

- Logistics coordination: Ensuring products are dispatched according to your needs

Why Choose a UK-Based Contract Manufacturer?

Geographical proximity influences nearly every aspect of the manufacturing relationship. When your contract manufacturer operates within the UK, several operational advantages become immediately apparent.

Faster lead times: Products can move from production line to your distribution centre within days rather than weeks, allowing you to respond quickly to demand fluctuations or market opportunities. This responsiveness becomes particularly valuable during product launches or seasonal peaks.

Regulatory alignment: UK manufacturers operate within the same compliance framework as your business. Understanding the requirements set by the Food Standards Agency reduces the risk of non-compliance and simplifies documentation for product approvals.

Enhanced quality oversight: Physical proximity enables you to:

- Visit production facilities and observe processes firsthand

- Build direct relationships with production teams

- Conduct more effective facility audits

- Resolve quality concerns faster during production runs

Improved communication: Working across the same time zones and business culture means technical discussions, specification changes, and production updates happen in real time rather than being delayed by time differences.

Supply chain stability: When raw materials, production, and distribution all occur within a contained geographic area, you reduce dependence on international shipping and the variables that could disrupt your production schedule.

What Regulatory Requirements Should UK Contract Manufacturers Meet?

Operating as a food supplement manufacturer in the UK requires compliance with a defined regulatory framework. Understanding these requirements helps brands evaluate whether potential manufacturing partners maintain necessary standards.

Essential certifications include:

- BRC Global Standards: Demonstrates food safety management systems recognised throughout the retail and food service sectors

- Informed Sport: Essential for products targeting athletes subject to anti-doping regulations

- Soil Association organic: Verifies products meet organic standards throughout sourcing and production

- Halal and Kosher certifications: Required for products serving specific dietary requirements

Quality control standards: Research from the Malaysia School of Pharmacy highlighted that consumers strongly preferred nutraceuticals proven with clinical evidence of no side effects and clear effectiveness. As such, comprehensive quality control standards are essential for market success.

Traceability requirements: Manufacturers must track raw materials from supplier through production to finished product, enabling rapid identification of any materials involved in quality issues. Batch records document every step of production, creating an auditable trail that demonstrates adherence to specifications.

How Do You Choose the Right UK Contract Manufacturer?

Selecting a manufacturing partner requires systematic evaluation across multiple criteria.

Key evaluation criteria:

Capability Assessment

- Can they produce your specific product formats (capsules, powders, tablets)?

- Do they have equipment and expertise to handle each format?

- Do they provide formulation development support or only execute pre-defined specifications?

Capacity Evaluation

- Can they handle your current volumes?

- Can they scale production as your brand grows?

- Do they offer flexible minimum order quantities for market testing?

Accreditation Verification

- Do they hold BRC accreditation (particularly important for major retailers)?

- Do they have Informed Sport certification (essential for sports nutrition)?

- Can they provide evidence of current certification status?

Track Record Review

- Do they have experience with similar products?

- Can they provide examples of comparable work?

- Will they share references from brands with similar needs?

Transparency Standards

- Do they communicate clearly about capabilities and limitations?

- Do they provide realistic delivery estimates?

- Will they share detailed information about testing protocols and quality procedures?

Communication Quality

- How responsive are they during initial enquiries?

- Will you have direct access to technical staff when needed?

What Are Common Challenges When Working with Contract Manufacturers?

Brands outsourcing manufacturing often encounter recurring challenges. Understanding these issues helps you evaluate how potential partners address them.

Quality inconsistency between batches

Quality variation creates operational problems and risks damaging brand reputation. Strong manufacturers address this through:

- Statistical process control to monitor production parameters

- Multiple supplier qualifications to reduce raw material variability

- Comprehensive testing that catches variations before products leave the facility

- Documented production parameters for every batch to identify root causes

Extended lead times and delays

Production delays cascade through inventory planning and customer commitments. Experienced manufacturers mitigate this by:

- Maintaining buffer stock of common raw materials

- Using production planning systems that optimise equipment utilisation

- Providing realistic timelines based on current capacity

- Communicating proactively when factors might affect schedules

Communication gaps

Unclear communication creates misunderstandings about specifications or delivery expectations. Strong manufacturers prevent this through:

- Dedicated account management for each client

- Regular communication cadences with proactive updates

- Documentation systems that make information readily accessible

- Direct access to technical staff when needed

Inadequate formulation support

Many brands lack internal expertise to develop optimal formulations. Experienced manufacturers provide value by:

- Employing qualified nutritionists and food technologists

- Guiding formulation decisions based on market trends and regulations

- Identifying potential issues early in development

- Helping brands avoid costly mistakes before production

How Does Rain Nutrience Support UK Brands?

Rain Nutrience operates as a full-service contract manufacturer based in Devon, with over 20 years of experience producing nutraceutical products, dietary supplements, and powdered blends for UK and international brands.

Certifications and capabilities:

- BRC-graded facilities for food safety

- Informed Sport certification for sports nutrition products

- Soil Association organic certification

- Halal Food Authority approval and KLBD Kosher certification

- Powder blending using IBC and sub-assembly systems

- Capsule and tablet manufacturing

- Sachet packaging and co-packing services

Formulation and development support:

The formulation development team includes experienced nutritionists and food technologists who provide:

- Ingredient selection based on efficacy and market trends

- Stability testing to confirm shelf life

- Dosage optimisation balancing effectiveness with cost

- Regulatory guidance ensuring UK compliance

Production and quality:

- Flexible minimum order quantities for both emerging and established brands

- Raw material testing on receipt

- In-process checks during production

- Finished product testing before release

- Dedicated account management for each client

- Regular communication and proactive updates

For brands evaluating Rain Nutrience as a potential manufacturing partner, the company provides facility tours, technical consultations, and detailed information about capabilities, certifications, lead times, and pricing structures.

Selecting Your UK Contract Manufacturing Partner

The decision to outsource production represents a significant commitment that affects product quality, operational efficiency, and brand reputation. Your choice of contract manufacturer influences whether you can deliver products on schedule, maintain consistency across batches, and scale production to meet demand.

UK-based manufacturers offer advantages in logistics, regulatory alignment, communication, and supply chain stability that international partners cannot match. When evaluating potential partners, prioritise capability, capacity, accreditation, track record, transparency, and communication quality.

Understanding common outsourcing challenges and how manufacturers address them helps you ask informed questions during evaluation. The manufacturers who acknowledge potential issues and explain their mitigation strategies typically prove more reliable than those who minimise challenges.

The investment in thorough evaluation pays dividends through reduced operational disruption, improved product quality, and relationships that support your business through different growth stages. For brands ready to explore UK contract manufacturing partnerships, begin by documenting your specific requirements across product formats, volumes, timeline expectations, quality standards, and regulatory needs.

Additional Resources for UK Contract Manufacturing

Manufacturing guidance:

- Co-Manufacturing in the Nutraceutical Industry

- Choosing the Right Vitamin and Supplement Manufacturer

- Why Experience Matters in Supplement Manufacturing

Industry knowledge:

Quality and compliance:

Ready to discuss your manufacturing requirements? Contact Rain Nutrience for a detailed conversation with a member of the team.

FAQs

- What is a UK contract manufacturer?

A UK contract manufacturer is a third-party production specialist that manufactures products on behalf of your brand according to agreed specifications, quality standards, and volumes. They handle formulation, production, packaging, and logistics while you retain brand ownership. - Why should I choose a UK-based contract manufacturer?

UK manufacturers offer shorter lead times, regulatory alignment with UK standards, easier facility oversight, better communication through shared time zones, and stronger supply chain resilience compared to international alternatives. - What services do contract manufacturers provide?

Services typically include formulation development, ingredient sourcing, stability testing, batch production, packaging, labelling, quality control, warehousing, and delivery logistics. - What certifications should a UK contract manufacturer hold?

Look for BRC accreditation and relevant specialist certifications such as Informed Sport for sports nutrition, organic certifications, or religious dietary certifications depending on your product requirements. - How do I evaluate potential manufacturing partners?

Assess their production capabilities, capacity to handle your volumes, quality certifications, track record with similar products, minimum order requirements, communication quality, and transparency about processes and timelines. - Can contract manufacturers help with product formulation?

Many UK contract manufacturers provide formulation development services, including ingredient selection, stability testing, regulatory guidance, and optimisation of existing recipes. - How does Rain Nutrience support UK brands?

Rain Nutrience provides end-to-end contract manufacturing including formulation support, flexible MOQs, multi-format production capabilities, comprehensive quality testing, and transparent communication throughout the production process.

A contract manufacturer operates as an extension of your business, producing finished products that meet your specifications without requiring you to build or operate your own production facility.

A contract manufacturer operates as an extension of your business, producing finished products that meet your specifications without requiring you to build or operate your own production facility.